What

When

The PDCA/Deming Cycle is used to monitor quality, optimize operations, improve processes, or address complex problems that require thorough investigation and evidence.

When picking a problem-solving tool like PDCA, it is important to think about the issue’s complexity, urgency, and type:

JDI ("Just Do It")

Basic, everyday problems that one person or a small group can quickly fix without formal methods are good for just-do-it (JDI) solutions.

The JDI (Just Do It) method is ideal for straightforward issues that individuals can resolve through immediate action and common sense, without requiring formal procedures or extensive documentation

PDCA

The PDCA/A3 Method helps teams to plan, implement, and check solutions in a structured way, for internal problems that need order but are not pressing.

The PDCA (Plan-Do-Check-Act) cycle is a continuous improvement method that guides teams through a systematic process of planning actions, implementing changes, checking results, and acting on lessons learned for ongoing improvements.

A3

The PDCA/A3 Method helps teams to plan, implement, and check solutions in a structured way, for internal problems that need order but are not pressing.

The A3 Method, named after the paper size traditionally used for the report, is a structured problem-solving approach that tells the complete story of a problem on a single page, forcing concise documentation while walking through background information, current conditions, root cause analysis, proposed countermeasures, and follow-up actions.

8D Report

The 8D (Eight Disciplines) process is specifically designed for complex quality issues and customer complaints, requiring a thorough, documented approach that includes containment actions, root cause analysis, and verification of corrective measures.

6σ Six Sigma

Six Sigma (6σ) represents the most rigorous and resource-intensive methodology, typically reserved for chronic, high-impact problems that require statistical analysis and long-term process improvement to achieve near-perfect quality levels.

Why

The Deming Cycle offers a clear method to prevent hasty decisions, checks effectiveness with data, and encourages ongoing learning through repeated steps. Deming pointed out that it is essential for gaining better understanding and making systematic improvements instead of short-term solutions.

Principles

Iterative Improvement: Ongoing and Small Enhancements Instead of One-Time Fixes

PDCA forms the backbone of iterative improvement by enabling teams to make small, measured changes instead of risky overhauls. Each cycle of planning, implementing, measuring, and standardizing creates opportunities for stakeholder feedback and progressive refinement. This systematic approach ensures organizations learn continuously while gradually reducing process variations and operational risks.

Data-Driven Decision-Making: Using Data to Assess Effectiveness and Direct Actions

Data-driven decision-making is central to the PDCA cycle, where actions are informed by data instead of guesses or feelings. In the “Check” step of PDCA, data gathered during the change is reviewed to measure its success. This helps to decide whether to keep, alter, or discard the method. By continually looking at data to assess performance and results, organizations can make smart adjustments that align with their quality aims and improve processes.

Standardization: Setting Consistent Ways to Implement and Review Improvements

Standardization in the PDCA cycle means creating dependable methods for making changes and evaluating results consistently. This is particularly important in the “Act” phase, where effective practices from the cycle are recorded and made the standard for the whole organization. By making and using standards, organizations can make sure that improvements stick and can be done again with the same results.

Feedback Loops: Using Feedback to Improve Processes in Every Cycle

Feedback loops are vital to the PDCA cycle, as they refine processes based on practical insights and input from stakeholders. In the “Check” and “Act” phases, feedback is collected from those involved or affected by the process, like employees, customers, or other interested parties. This input gives important insight into what works and what needs changes, guiding the next “Plan” phase. By consistently including feedback, organizations can adjust processes to meet quality expectations and boost performance. This fosters a culture of continuous learning and quick responsiveness to change.

How To

1. Plan

The “Plan” phase is the start of the PDCA cycle. It starts with finding and clearly stating the problem so everyone understands.

Then, root cause analysis is done, often using tools like the 5 Whys or Fishbone Diagram to find the main issues causing the problem. After understanding the root cause, clear goals that can be measured are set to help guide the improvement. Next, a plan is made that lists each step needed to tackle the root cause, and success measures are outlined to check how effective the actions are. These measures create a clear way to evaluate outcomes in later phases, focusing the testing process and ensuring actions are in line with the desired results.

For developing the plan the following questions may be answered:

- Which document need to be updated?

- Work instructions, Drawings, Control Plans, FMEAs, Computer programs, etc.

- Which document need to be updated?

- Which employees require re-training?

- Operators, Inspectors, Engineers, other Support personnel

- Which employees require re-training?

- Which Organizations have to be notified?

- Internal departments, Suppliers, Customers

- Which Organizations have to be notified?

- What are the new problems caused by changes and what is their resolution?

- How these problems to be addressed, e.g. using Risk Assessments, FMEA, Control Plan?

- Who is in lead for the tasks and implementation dates?

- How will progress be monitored and measured?

- What is the Contingency plan in case of things go wrong?

- When will temporary containment actions be stopped?

2. Do

In the “Do” phase, the plan made earlier is implemented, but only on a small scale to minimize risk and see if it works. This phase acts like a trial, aiming to see how the solution acts in real-life without large changes. Data is collected during this phase to see how the changes affect key metrics, including any unexpected results. Observations are also noted, as they can show details or insights that numbers alone might miss. This information and feedback will be crucial in the “Check” phase, helping determine if the plan needs changes, should be scaled up, or requires further refinement.

1. Execute the Plan by using established processes:

• Document control

• Engineering Changes

• Customer notification

• Supply Chain processes

• Training processes

2. Identify the effective date of changes

Project Management Tools:

- Gantt Charts (Top Level)

- Task Lists (Detail Level)

- Reports

3. Check

The “Check” phase focuses on carefully reviewing the test results. The data and observations gathered during the “Do” phase are looked at to see if the initial goals were met and to find any differences from expected results. If the results align with what was outlined in the “Plan” phase, the solution is seen as effective. If not, the reasons for the discrepancies are explored to understand needed adjustments. This step is vital for confirming the approach and deciding if it can be scaled up or needs alteration. By evaluating the test results thoroughly, organizations can make better decisions to avoid scaling ineffective solutions.

The “check” phase is vital to confirm that the project or process improvement effort is progressing correctly and meeting its goals. It provides an opportunity to spot any problems or changes from the plan early, allowing for prompt corrective measures when necessary. Important aspects to be checked are:

- Monitor progress and assess resources required to meet deadlines

- Evaluate performance data to confirm that improvements are taking effect

- Analyze costs to make sure financial outcomes align with expectations

- Verify that no unforeseen issues are occurring (in areas like quality, efficiency, safety, etc.).

4. Act

In the “Act” phase, if the “Check” phase shows success, the solution is put into action on a larger scale. This means applying the changes across the organization or specific departments to standardize the improvement. When accepted, the solution is documented as the new standard operating procedure (SOP) to ensure consistency. However, if the “Check” phase shows there are still improvements to be made, the PDCA cycle starts again with a refined plan to continue enhancing the approach. The “Act” phase highlights the need for flexibility to ensure only effective solutions are adopted while allowing for changes as necessary.

The “Act” phase closes the cycle. It might go back to earlier phases if necessary or proceed to new chances if the current project succeeds. This method reflects principles of continuous improvement and flexible management in project execution.

Changes get made based on need:

- Reapply containment actions if issues continue and update corrective actions (going back to the problem-solving and “Plan” phase)

- Reallocate resources to get execution back on course

- Advance to the next opportunity if everything is finished and meeting expected results

Benefits

Reduces Risk

Testing Small Changes Limits Disruption and Lowers Risk of Big Problems

One main advantage of PDCA is that it lowers risk through small, controlled tests. By first making changes on a small scale, PDCA helps organizations see the effects without causing major disruptions or big problems in key operations. This careful method lessens the chances of negative outcomes since only successful and well-reviewed improvements move forward. Additionally, isolating each change in a test setting allows teams to fix minor problems before they become serious, making PDCA a safe way to introduce changes in complicated or critical processes.

Encourages Continuous Improvement

Organized Problem-Solving Reduces Resource Waste and Boosts Operational Efficiency

PDCA’s organized approach to problem-solving greatly boosts efficiency by systematically finding and tackling the root causes of issues. Through careful planning, controlled execution, and thorough evaluation, PDCA reduces wasted time on ineffective solutions, focusing on targeted, data-based improvements instead. This approach cuts down on trial-and-error and ensures resources are used wisely to achieve real results. By enhancing processes step by step, organizations using PDCA can streamline workflows, lessen bottlenecks, and remove unnecessary steps. The structure of the cycle also aids in clear communication and teamwork, allowing teams to collaborate effectively for consistent outcomes that improve overall operational.

Improves Efficiency

Organized Problem-Solving Reduces Resource Waste and Boosts Operational Efficiency

PDCA’s organized approach to problem-solving greatly boosts efficiency by systematically finding and tackling the root causes of issues. Through careful planning, controlled execution, and thorough evaluation, PDCA reduces wasted time on ineffective solutions, focusing on targeted, data-based improvements instead. This approach cuts down on trial-and-error and ensures resources are used wisely to achieve real results. By enhancing processes step by step, organizations using PDCA can streamline workflows, lessen bottlenecks, and remove unnecessary steps. The structure of the cycle also aids in clear communication and teamwork, allowing teams to collaborate effectively for consistent outcomes that improve overall operational.

Increases Stakeholder Engagement

PDCA Involves Team Members in Problem-Solving, Boosting Involvement and Morale

Another important benefit of PDCA is that it boosts stakeholder engagement by actively involving team members in solving problems. By collecting input from those directly affected by a process, PDCA makes sure that improvements are practical and meet the team’s needs. This collaborative method creates a sense of ownership and responsibility since team members see their contributions leading to positive changes. This involvement raises morale, as individuals feel appreciated and acknowledged, and increases buy-in, with those involved more likely to support new practices. Engaging stakeholders in this manner builds a culture of mutual responsibility for quality, resulting in stronger commitment and lasting improvements.

Limitations

Time-Consuming

PDCA’s Repetitive Process Can Delay Decisions in Quick Environments

PDCA’s repetitive method is good for careful problem-solving but can take a lot of time, especially where fast decisions are needed. The process has many steps—planning, testing, evaluating, and adjusting—that must be done carefully to get dependable results. This level of detail can cause issues for organizations with tight deadlines, where quick responses are essential. In these situations, the PDCA process might seem too slow or even hinder decision-making, as it values caution over speed. Thus, organizations should think about how urgent an issue is before choosing PDCA, as the cycle’s structured approach may not work well for problems needing quick fixes.

Limited Scope

PDCA’s Focus on Small Improvements Might Not Solve Big Problems

PDCA works well for small improvements but may struggle with major, deep-rooted problems that need broad changes. The cycle is meant for gradual tweaks and adjustments, making it suitable for refining processes or fixing specific issues. However, this focus can limit its effectiveness when dealing with complex challenges that involve various interconnected elements or affect different areas of an organization. For instance, in cases of cultural issues or fundamental structural challenges, PDCA may not be able to create significant change, as these situations usually need a more comprehensive, organization-wide strategy instead of just small adjustments.

Requires Consistent Data

Poor Data Quality Can Hurt the Effectiveness of PDCA

PDCA depends on data to evaluate changes and inform decisions, making consistent and accurate data collection vital for its success. Without trustworthy data, it is hard to determine if changes are really effective or to spot areas needing improvement. When data is incomplete, outdated, or inconsistent, the results of the PDCA process can be misleading, leading to poor solutions or wrong decisions. Organizations using PDCA need strong systems for data collection and analysis, as any flaws in data quality can weaken the cycle’s effectiveness. This data reliance can be challenging in environments where gathering or verifying data is tough, potentially affecting the accuracy and trustworthiness of the PDCA method.

Best Practice

Focus on Simple, Specific Issues for Better PDCA Use

Beginning with small issues is key to effectively using the PDCA cycle. When organizations focus on specific, simpler problems, they can apply PDCA more accurately and with lower risk. Trying to solve large, complicated problems right away can be daunting and may result in scattered efforts or failure. Instead, addressing smaller, clearly defined problems allows teams to practice the PDCA steps—Plan, Do, Check, Act—within a controlled setting, enhancing their understanding of the process and building trust in its use.

A manufacturing company, for example, may begin by focusing on cutting down defects in one production line. By addressing this particular problem, the team can find root causes, try a fix, and evaluate its effectiveness without facing challenges from bigger changes. This approach not only makes improvements easier to measure and achieve but also brings rapid successes that demonstrate the advantages of PDCA to the entire organization. As teams build their experience and achieve successes with minor projects, they can progress to more difficult issues, broadening the PDCA cycle to promote ongoing improvement.

Include All Relevant Stakeholders for Better Insights and Easier Implementation

Include All Relevant Stakeholders for Better Insights and Easier Implementation Involving the whole team and relevant stakeholders is vital for successfully using the PDCA cycle. Including various viewpoints leads to a better understanding of the issue and encourages teamwork in finding solutions. When team members take part in every step of PDCA, from planning to acting, they are more likely to share valuable insights, spot challenges, and create practical solutions that suit the organization’s needs.

For instance, in a healthcare environment looking to enhance patient discharge procedures, input from nurses, doctors, administrative staff, and even patients can give a complete picture of the problems. Each group can provide unique insights into different parts of the discharge process, from clinical steps to administrative tasks and patient experiences. This collaborative setup not only enhances problem-solving but also boosts commitment to the changes made. When team members feel their input is valued, morale and drive increase, leading to a smoother implementation and lasting improvements.

Tools Like the 5 Whys or Fishbone Diagrams Can Support the "Plan" Stage by Finding Core Problems

Root cause analysis (RCA) is essential in the "Plan" phase of the PDCA cycle, as it aids organizations in finding the basic causes of issues instead of just treating symptoms. Using RCA tools like the 5 Whys or Fishbone (Ishikawa) Diagrams can greatly improve the planning stage by offering structured ways to identify hidden problems.

The 5 Whys method involves repeatedly asking “why”—usually five times—to get to the root of an issue. For instance, if a company sees delays in product delivery, the first “why” might indicate late shipments due to production hold-ups. The next “why” may reveal that the hold-up is due to machinery failures, and this continues until the main cause is discovered. This approach is straightforward, easy to apply, and effective for simple issues.

Conversely, the Fishbone Diagram provides a broader view by organizing potential causes into categories like People, Processes, Equipment, Materials, Environment, and Management. This visual tool helps teams thoroughly investigate all possible factors related to a problem, making sure no cause is missed. For example, in assessing a drop in product quality, a Fishbone Diagram can help uncover if the issue stems from staff training, equipment upkeep, raw material quality, or other factors.

Using these RCA tools in the “Plan” phase guarantees that action plans are informed by a solid understanding of the core causes of the problem. This leads to more focused and effective solutions, minimizing the chances of recurring issues and improving overall quality efforts. Furthermore, employing RCA tools encourages critical thinking and analytical skills among team members, fostering deeper involvement in the problem-solving process and supporting a culture of ongoing improvement.

Write Down Data and Observations to Ensure Clear and Traceable Improvements

Careful documentation of each phase in the PDCA cycle is crucial for transparency, accountability, and continuous learning. Recording data and observations at each stage—Plan, Do, Check, Act—provides a clear record of the problem-solving process, allowing organizations to track progress, assess effectiveness, and make decisions based on solid evidence.

In the “Plan” phase, documentation needs to have a clear problem statement, findings from root cause analysis, set objectives, and a thorough action plan with detailed steps and criteria for success. This helps establish a strong base and serves as a guide throughout the cycle.

During the “Do” phase, it is important to record how the implementation goes, noting any changes from the plan, challenges faced, and initial results to keep track of all relevant data for future review.

The “Check” phase relies on the records and observations to see if the goals were achieved and to spot any differences or surprising outcomes. Clear documentation supports a detailed analysis, helping teams know what succeeded, what failed, and the reasons behind them.

Lastly, in the “Act” phase, documenting choices made—whether to keep successful changes in place or modify the plan for more improvement—ensures that Lessons Learned remain accessible for future use.

Pizza-Example

Zero-Defect Pizza Production using PDCA

1. Plan

The Zero-Defect Pizzeria saw ongoing problems with the quality of pizzas, like dough texture differences, uneven baking with undercooked or burnt spots, and irregular topping placement. These problems led to customer complaints, higher waste, and fewer repeat customers.

The management started the PDCA cycle by clearly describing the issue. They used Fishbone Diagrams to find root causes, which pointed to inconsistent dough-making methods, changing oven temperatures, and no set measures for toppings.

Understanding the root causes helped the team set clear goals:

1. Achieve uniform dough texture by standardizing how it is prepared.

2. Ensure thorough baking by adjusting ovens and setting clear baking times.

3. Standardize topping distribution for consistent pizzas.

They created an action plan for each goal:

1. Dough Preparation:

- Use a standard recipe with precise measurements and mixing times.

- Train staff on these new steps and use a dough thermometer.

2. Oven Calibration:

- Calibrate all ovens to ensure equal temperature.

- Set up a maintenance schedule to avoid temperature changes.

3. Topping Distribution:

- Make guidelines for each topping, including pre-measured containers and visual aids to assist staff.

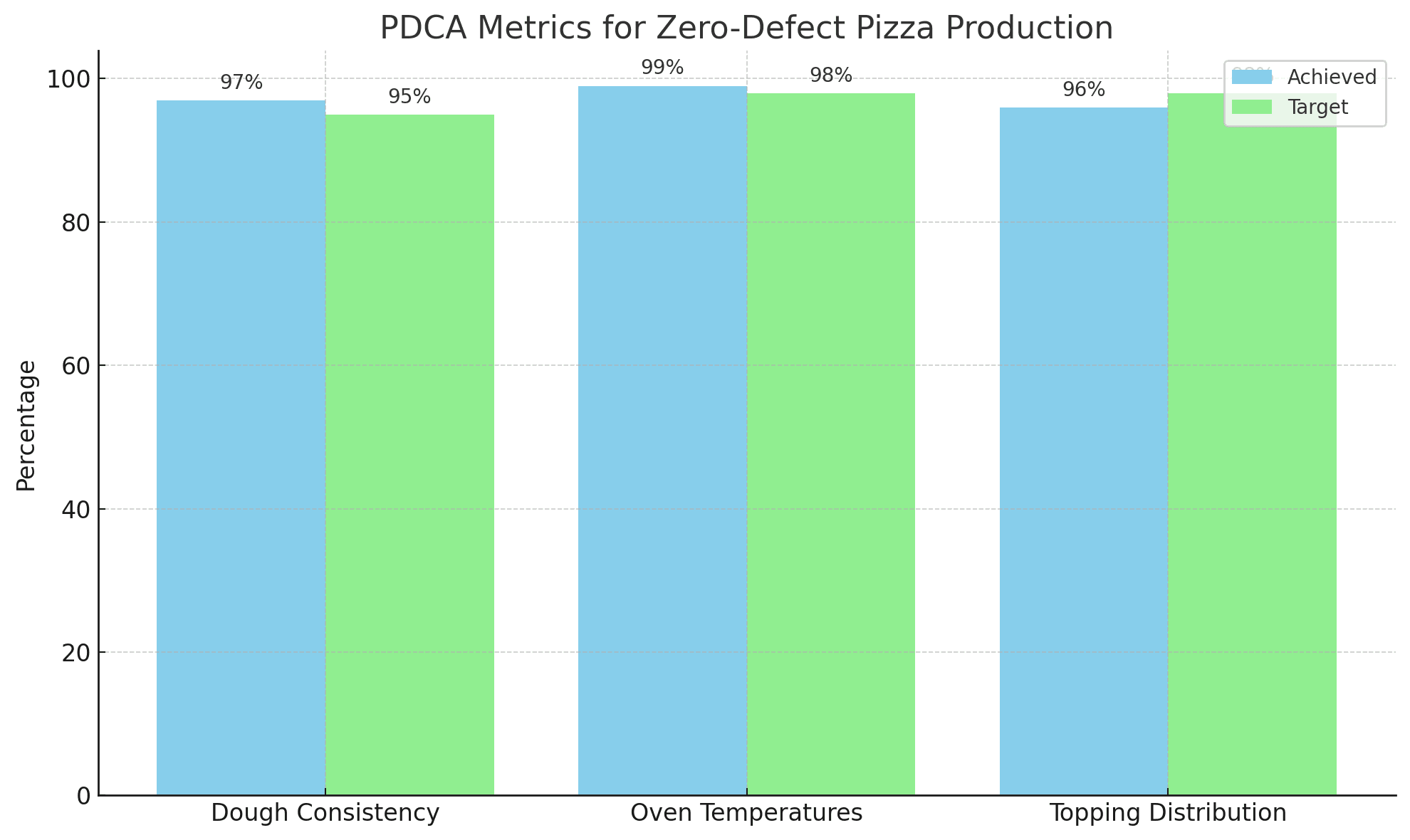

Success measures were set, such as

- reducing dough texture differences by 95%,

- keeping oven temperatures within ±2°C, and

- getting uniform topping distribution in 98% of pizzas.

They check these through regular quality inspections and customer feedback.

2. Do

In the “Do” stage, the pizzeria chose a busy location to test the new processes. Staff there received training on the new dough-making techniques, oven calibration methods, and topping guidelines. Dough thermometers and pre-measured containers were introduced to aid consistency.

The team kept careful records of various quality metrics:

1. Dough Consistency: Checked with dough thermometers and visual inspections.

2. Oven Temperatures: Monitored regularly to ensure stability.

3. Topping Distribution: Reviewed through random checks of finished pizzas for uniformity.

Staff gave feedback on the new methods, discussing challenges like adjusting to standards and needing extra training for new tools. Customer feedback was also collected through surveys and direct comments to see if pizza quality had improved.

3. Check

After six weeks of implementing the new procedures, the pizzeria entered the “Check” phase to see how effective the changes were. The collected data revealed significant improvements:

4. Act

In the “Act” phase, the pizzeria chose to expand the successful processes to all stores while fixing the inefficiencies found. They clearly wrote down the dough prep methods, oven settings, and topping portioning rules and added them to the company’s standard operating procedures (SOPs).

To fix the delays in pizza assembly, the team added more training focused on working faster while still being accurate and improved the kitchen layout to make applying toppings easier. They also looked into automated portioning tools to help with efficiency more.

The new processes were introduced to all pizzeria locations, along with a full training program to guarantee consistent use everywhere. Regular quality checks and customer feedback channels were set up to keep track of ongoing performance and find any new areas to improve.

Additionally, the team promised to do quarterly PDCA cycles to keep making pizza production quality better. This ongoing improvement focus made sure that the pizzeria upheld high standards, reduced mistakes, and consistently offered great pizzas to customers.

FAQ

What is PDCA?

The Plan-Do-Check-Act (PDCA) cycle, also known as the Deming Cycle, is a four-step process used to solve problems and improve operations. It emphasizes systematic planning, execution, evaluation, and corrective action to ensure continuous improvement in processes and quality management.

PDCA was named after W. Edwards Deming, who popularized it as a method for achieving structured and sustainable improvements in organizations.

When is PDCA used?

The PDCA cycle is widely applied in:

Quality Management – Monitoring and optimizing product or service quality.

Process Improvement – Enhancing business and production workflows.

Problem-Solving – Addressing complex challenges through data-driven investigation.

Innovation & Development – Refining new products and services through continuous iteration.

PDCA is effective in both small-scale process optimizations and large-scale organizational improvements, as it provides a structured, repeatable approach to addressing inefficiencies.

Why is PDCA important?

The PDCA cycle offers a systematic way to:

Avoid hasty decisions – Ensuring solutions are well-thought-out and data-driven.

Check effectiveness with data – Using real performance measures to assess success.

Encourage continuous improvement – Repeating the cycle to refine and optimize processes over time.

Rather than relying on short-term fixes, PDCA helps organizations develop a culture of ongoing learning and problem-solving.

What are the key principles of PDCA?

Iterative Improvement – Making small, ongoing refinements instead of one-time fixes.

Data-Driven Decision-Making – Using real data to evaluate effectiveness and guide actions.

Standardization – Establishing consistent methods for implementing and reviewing improvements.

Feedback Loops – Using lessons learned from each cycle to enhance future iterations.

How is PDCA performed?

1. Plan

Define the problem and analyze its root cause (using tools like 5 Whys or Fishbone Diagrams).

Set measurable improvement goals.

Develop a step-by-step action plan with success criteria.

Identify necessary resources, responsibilities, and risk mitigation measures.

2. Do

Implement the plan on a small scale to test its feasibility.

Collect data and document observations during execution.

Use controlled trials or pilot projects to minimize risk.

3. Check

Analyze results to determine if goals were achieved.

Compare actual performance against expected outcomes.

Identify gaps, discrepancies, or unexpected challenges.

Assess whether the plan needs adjustments before full implementation.

4. Act

If the solution is successful, implement it organization-wide and standardize the new process.

If improvements are needed, refine the plan and repeat the PDCA cycle.

Document lessons learned for future problem-solving efforts.

What are the benefits of PDCA?

Reduces Risk – Testing small changes first helps avoid large-scale failures.

Encourages Continuous Improvement – Fosters a culture of ongoing learning and adaptation.

Improves Efficiency – Ensures processes are optimized for better performance.

Increases Stakeholder Engagement – Encourages cross-functional collaboration and teamwork.

What are the limitations of PDCA?

Time-Consuming – Repeating cycles can slow down decision-making in fast-paced environments.

Limited Scope – May not be ideal for urgent, large-scale transformations.

Requires Consistent Data – Success depends on accurate data collection and analysis.

What are best practices for PDCA implementation?

Start Small – Apply PDCA to simple, specific issues before scaling up.

Involve the Team – Engage employees and stakeholders for diverse insights and better adoption.

Use Root Cause Analysis Tools – Techniques like 5 Whys and Fishbone Diagrams enhance problem diagnosis.

Document Each Phase – Keep records of all steps, data, and lessons learned to ensure process transparency.

Standardize Successful Changes – Once improvements are verified, incorporate them into regular workflows.