Up to 20% of revenue is spent on quality, whereof quality problems cause the majority of these costs

Quality Problems cause companies loosing money and customers, while their quality experts have to solve them with inefficient processes and tools

Up to 20% of revenue is spent on quality, whereof quality problems cause the majority of these costs

Quality problems combined with inefficient quality processes and tools harm quality teams

Quality problems have an impact on customer’s satisfaction and readiness for new business

Quality problems cause disorder across the supply chain with financial and customer impact

Quality problems and related costs will increase in the future without effective countermeasures and the focus on the entire supply chain

Technology and social change lead to higher requirements for product and service quality

Less qualified people while increasing loss of product, process and quality knowhow

Higher customer expecations increase the complexity of products and their supply chains

Higher regulatory and compliance requirements increase the impact of quality problems

Correctly applied Quality Methods support quality teams to

– detect defects earlier

– protect customers faster

– solve root causes better

“We know first”

The earlier a defect or potential quality problems is detected in your supply chain and the lower the value level, the lower the overall failure costs.

Process incidents and problem solving methods like 8D, A3 or Six Sigma without frictions with your internal and external process partners.

Constant transparency on incidents and problems priority as well as on related risk for your oganisation.

Enable your n-tier process partners in your supply chain by sharing state-of-the-art quality processes and methods.

Proactively react to impending problems by sending surveys to your supply chain.

“Close all gates”

Rapid and efficient containments prevents defects from reaching customers.

Personalized alerting to potential impacts speeds up efficient and effective containment across the entire supply chain.

Rapid and efficient containment secures the supply chain and prevents defects from reaching the customers.

“No defect twice”

Reduce the amount and severity of quality problems and the workload for your quality experts.

Gather your best people from your network, find the root cause and fix it forever with state-of-the-art Q-methods and AI.

Full transparency and traceability of all occurred expenses avoid legal disputs and emphazies the monetary impact of quality issues.

Prevent quality issues with integrated systems and methods that detect and eliminate defects before they happen.

Spot potential problems before they emerge using predictive analytics that turn data into preventive action.

I have a confession to make, which may shock a lots of my colleagues: “I do not understand the ISO......

Have you ever wondered why some problem-solving efforts succeed while others fail? I have seen thousands of 8D reports and......

“What is quality?” or “What are you exactly doing in quality?”, sometimes people, my family or friends are asking. After......

“I’d rather clean the toilets in our office building than doing that.” That was my reaction when I was asked......

Solving Problems with the Ishikawa-/Fishbone Diagram: From Mistakes to Perfect Solutions

“Make Quality, not Spreadsheets”

From Scapegoat to Problem-Solver.

“No negative Surprises”

Reducing failure costs is an effective way to improve current and future profit margins, while boosting customer satisfaction and sales.

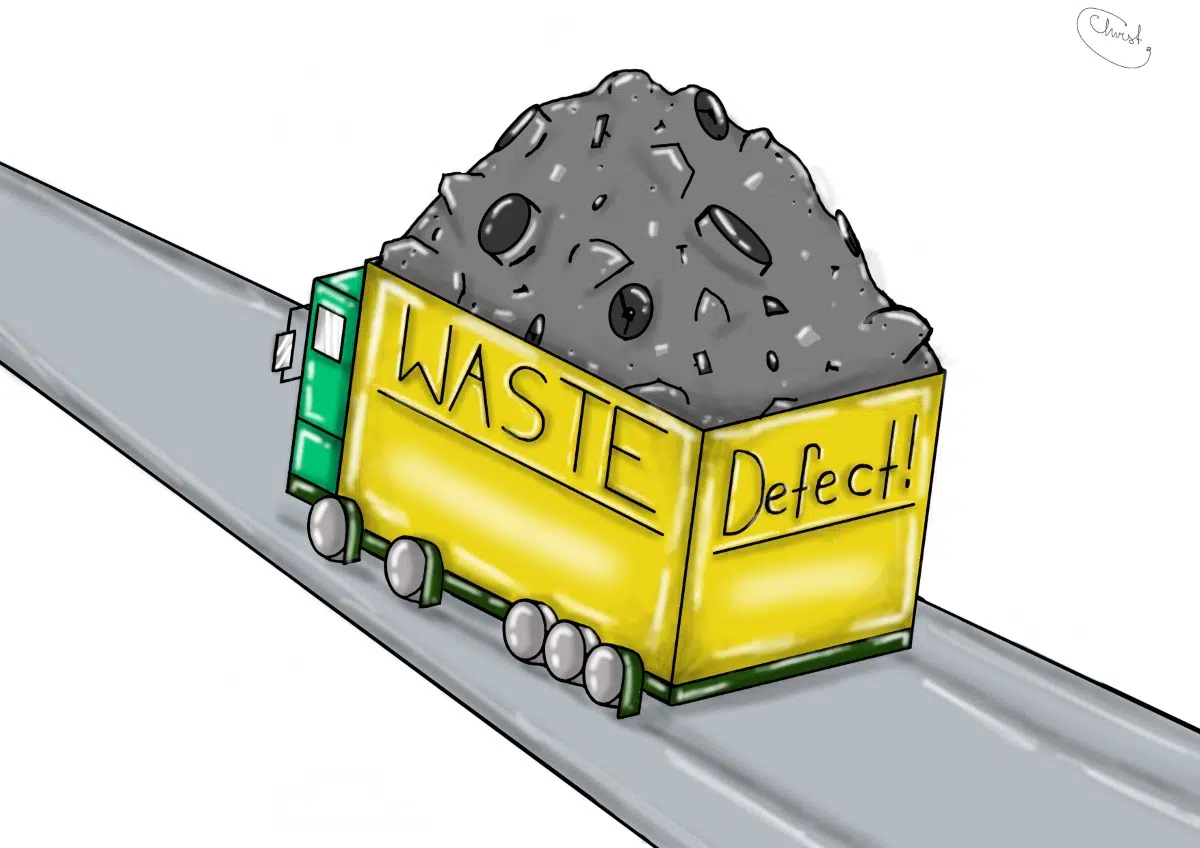

“Defects are Waste”

Reducing defect reduces direct waste like scrap and your CO2 foot print.

Rapid amortisation due to

– high quality costs

– low implementation costs

Between 5% and 15% of revenue is spent on quality. Whereof up to 70% on internal and external defect costs.

After all, what is a better return on investment than looking into the happy and smiling faces of your customers and employees?

"We-have-always-done-it-this-way" is a valid options while quality problems mounting ... or at least till the next major quality incident.

If you too much money and time at your hand, just go for it. If you look for a better and faster way, just let us know.

5W2H Method: Solve Any Problem with 7 Simple Questions