what

Overall Equipment Effectiveness (OEE) is a key quality tool used in manufacturing and production fields to assess how well equipment and processes function.

It offers information on the performance of machinery and processes, aiding companies in finding areas needing enhancement.

OEE started in the 1960s as part of Total Productive Maintenance (TPM) in Japan. It became well-known in the 1980s and has since become a basic tool in Lean and Six Sigma methods.

When

Overall Equipment Effectiveness (OEE) is a metric often used in manufacturing to assess how well equipment or production lines work. It helps pinpoint losses, grasp production efficiency, and boost productivity by concentrating on three main factors: Availability, Performance, and Quality.

OEE can also be used in case of emergency or deviations to monitor and safeguard critical components, processes or supplier during launch phases.

why

The main goal of OEE tracking is to boost output by cutting downtime, lowering cycle times, and enhancing product quality. It assists companies to find and to fix issues and inefficiencies in their operations.

OEE is based on three key factors:

| 1. Availability | 2. Performance | 3. Quality |

|---|---|---|

| Availability in OEE shows how much time equipment is ready for making products. This number includes both scheduled and unscheduled downtime. A high availability score means the equipment is often ready to work with few breaks. To get high availability, companies need to do good maintenance, respond fast to problems, and manage quick changes. It's an important part of OEE because even the best equipment won’t help if it’s not ready. Businesses aim to improve availability so that production lines can operate smoothly and meet customer needs effectively. | Performance in OEE looks at how well equipment works compared to its best speed or design. It shows how effectively a machine or process is functioning. A good performance score means the equipment is working at or close to its highest output. Low performance can come from problems like incorrect settings, wear, or mistakes by the operator. Finding and fixing performance issues can boost productivity and output without needing more machines. It's important to adjust processes and improve equipment to reach high performance and reduce production slowdowns. | Quality in OEE shows how many defect-free products the machines make. It looks at how well the machines work to provide products that meet quality requirements. A good quality score means the machines are making products that mostly fit the needed standards with few mistakes or need for extra work. Keeping quality high is important for making customers happy and cutting down on waste during production. Companies put money into quality control, training, and improving processes to make sure machines keep making products that match or go beyond quality goals. Producing high-quality items makes customers happy and lowers production costs by reducing leftovers and extra work needed. |

How To

1. Determine the total available production time

To calculate the OEE, first find out how much total production time is available. This means you need to know how long the equipment or process is supposed to be ready for production. Usually, this is the scheduled production hours less any planned downtime for things like maintenance, breaks, and changeovers. It’s important to clearly understand the time when production can happen without any stops.

2. Calculate the actual production time

Once you determined the total production time, you must calculate actual production time. This is the time when equipment was working on production. To do this, take away any unplanned downtime, such as unexpected breakdowns and other interruptions, from the total production time. The outcome is the time the equipment was actually used for production.

3. Calculate the ideal cycle time

The ideal cycle time is the time needed for the machine to make one product at best speed, without any delays or problems. To find the perfect cycle time, you take the total production time available and divide it by how many units should be made in that time. This gives you a standard for how fast the machine could work if it ran at full efficiency.

4. Compute availability, performance, and quality percentages

After you have the real production time, you can calculate availability, performance, and quality percentages.

- Availability is the actual production time compared to the total available time, shown as a percentage.

- Performance is the actual production rate divided by the ideal cycle time, also shown as a percentage.

- Quality is the number of good products made compared to all products made, expressed as a percentage.

These three percentages are key parts of OEE, which represent the availability, performance efficiency, and quality of the products from the equipment.

5. Multiply these three percentages to get the OEE score

To get the Overall Equipment Effectiveness (OEE) score, just multiply the availability, performance, and quality percentages. This gives a single percentage that shows how well the equipment works. An OEE score of 100% means perfect performance—it means the equipment is working at its best, making products without defects and having no downtime. A lower score shows there is space for improvement in one or more of the three parts, making organizations aim to boost efficiency, quality, or availability to improve their OEE score.

Benefits

Detect issues before they develop into expensive customer problems

One lesser-known advantage of OEE tracking is its function as a preventative measure in keeping and improving equipment and processes. By consistently watching OEE data, companies can foresee possible problems and tackle them before they become big and costly issues. This is similar to having a crystal ball that shows weaknesses in the production system and future quality concerns.

Increased productivity and efficiency

A main advantage of using OEE is the notable increase in productivity and efficiency in manufacturing and production tasks. By assessing and reviewing how well equipment and processes perform, companies can find and remove bottlenecks, cut down on idle time, and optimize operations for better performance. This results in greater output with less time and fewer resources, which leads to higher profits and better competitiveness in the market.

Finding areas for process improvement

OEE gives important information about how equipment and processes work, helping organizations find where improvements are needed. By looking at OEE data, companies can spot ongoing problems, the main causes of inefficiencies, and chances for betterment. This data-based method allows teams to make specific process improvements, like cutting setup times, reducing equipment downtime, and simplifying workflows. Ongoing improvement efforts based on OEE data result in more efficient production processes.

Reduced downtime and maintenance costs

OEE helps companies to reduce unexpected downtime by spotting maintenance needs early. By watching equipment availability and performance, maintenance teams can plan preventive maintenance tasks before machines fail or run poorly. This leads to less downtime, fewer production interruptions, and lower emergency repair costs. Preventive maintenance, based on OEE data, not only helps the equipment last longer but also allows for overall cost savings.

Better product quality and customer satisfaction

Keeping product quality the same is very important in today’s markets. OEE is important for checking product quality by watching how equipment works and finding problems that might cause defects or changes in product specifications. When machines work well and within limits, they make good quality products all the time. This helps customers be happy because they get products that are good and meet their needs. A good reputation for quality products can help keep customers coming back and lead to good recommendations, which is also good for the company’s profits.

Limitations

OEE looks at how machines work but may miss outside factors

One restriction of using OEE is that it only looks at how machines perform in making products. While it gives useful information about machine efficiency, it does not consider outside issues that can affect production results. Problems like delays in the supply chain, quick shifts in demand, or outside quality concerns can lower productivity and quality but may not show up in OEE scores.

Companies should remember that OEE is a good tool, but it needs to be used with other data sources and a wider view to fully grasp and manage all factors that impact how they operate.

OEE might not show what causes inefficiencies.

OEE can highlight inefficiencies in production, but it might not identify what causes those inefficiencies. For instance, if OEE reports lower performance, it might not indicate whether it’s due to machine issues, lack of staff training, or other complicated reasons. To fix inefficiencies properly, more analysis and investigation into the root causes might be necessary.

Therefore, businesses should use OEE together with methods like root cause analysis to gain a fuller picture of the problems they face.

OEE needs precise data collection, which can take time and effort

Collecting accurate data is essential for OEE to be useful, but this can be a lengthy task. Getting real-time information on machine availability, performance, and quality needs dedicated resources, monitoring tools, and data recording methods. Any mistakes or holes in the data can harm OEE results.

Additionally, starting OEE tracking might require more training for staff to make sure data is collected correctly and consistently. While OEE provides significant benefits, companies should be ready to spend time and resources to ensure strong data collection and management for valuable insights from the tool.

Best Practice

Analyze OEE data on a regular basis to find trends and improvement areas

To get the most from OEE tracking, organizations need to set up a routine for checking and analyzing OEE data. Regularly reviewing this information helps to find trends in equipment performance and how efficient processes are. By looking at OEE metrics often, organizations can see ongoing problems or differences from ideal performance. This proactive method allows for quick actions to improve processes, boost equipment reliability, and raise overall operational efficiency. In short, being attentive to OEE data helps organizations to keep improving their operations for better outcomes.

Set up preventive maintenance times to reduce unexpected downtime.

Maintenance ahead of time is important for lowering unexpected downtime and improving how equipment works. Companies ought to use OEE information to help create maintenance schedules. By planning maintenance tasks based on how well equipment is performing and past data, companies can fix problems before they cause failures. Regular maintenance not only makes equipment last longer but also keeps it working well, which helps improve OEE scores. This method changes maintenance from a response to issues into a planned approach, leading to lower costs and fewer interruptions in production.

Bring together cross-functional teams to deal with OEE problems fully

OEE problems often touch various parts of a company, like machine upkeep, employee training, and improving processes. To solve these issues fully, it helps to bring together teams from different functions. Teams with members from maintenance, production, quality control, and management can share different viewpoints and skills to effectively address OEE challenges. This teamwork ensures that all parts of a problem are looked at, and solutions are applied in a complete way. Cross-functional teams also help improve communication and knowledge sharing within the company, fostering a culture of constant improvement focused on OEE tracking.

Pizza-Example

OEE Calculation for the Pizza backing machine of Zero-Defect Pizza

Zero Defect Pizza has bought a pizza-making machine and set up a production line, where the goal is to produce pizzas with no defects, ensuring high quality and efficiency in the process.

Every stage (dough making, sauce adding, topping putting, baking, and packing) needs to work well for good output and no mistakes. The aim is to improve OEE by making sure there is high uptime, best performance, and no errors in the final item.

Step 1: Define Target and Actual Production

- Planned Production Time: 8 hours (or 480 minutes) in a shift

- Ideal Cycle Time: 1 pizza every 2 minutes (0.5 pizzas per minute)

- Total Pizza Production Goal: 240 pizzas per shift (assuming ideal conditions)

Step 2: Calculate Availability

Availability measures the time the line is actually operational versus the planned production time.

- Unplanned Downtime (e.g., machine breakdowns, supply issues): 50 minutes

- Actual Operating Time: 480 minutes (total shift time) – 80 minutes (total downtime) = 400 minutes

Availability Calculation:

Planned Downtime (e.g., cleaning, setup, etc.): 30 minutes

Step 3: Calculate Performance

Performance measures if the line is running at its optimal speed.

- Ideal Production at 100% Performance: 400 minutes × 0.5 pizzas per minute = 200 pizzas

- Actual Production: 180 pizzas (due to minor slowdowns during topping and baking stages)

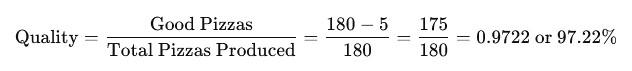

Step 4: Calculate Quality

Quality measures the ratio of defect-free pizzas to the total produced pizzas.

- Total Pizzas Produced: 180

- Defective Pizzas: 5 pizzas (e.g., undercooked, incorrect toppings, uneven baking)

Step 5: Calculate OEE

OEE is the product of Availability, Performance, and Quality:

Interpretation of the Results

The OEE score of 72.92% shows there is need for improvement.

- Availability (83.33%): There was notable unexpected downtime (50 minutes) that might be lessened with better preventive care or quicker reactions.

- Performance (90%): Small slowdowns took place, likely during the topping or baking phases, which points to a need to make these steps more efficient.

- Quality (97.22%): A good quality score is encouraging, but to get to “zero defects,” we must fix the five defective pizzas, possibly by improving quality checks during baking or topping.

FAQ

What is OEE (Overall Equipment Effectiveness)?

OEE, or Overall Equipment Effectiveness, is a key performance indicator used in manufacturing to measure how efficiently equipment and processes are operating. It assesses availability, performance efficiency, and product quality to provide insights into operational efficiency.

Where is OEE tracking used?

OEE tracking is widely used in manufacturing industries, including automotive, electronics, pharmaceuticals, and food production, to optimize equipment and processes.

What is the main objective of OEE tracking?

The primary objective of OEE tracking is to maximize productivity by minimizing downtime, reducing cycle times, and improving product quality.

When was the OEE developed?

OEE was developed in the 1960s in Japan as part of the Total Productive Maintenance (TPM) methodology and gained prominence in the 1980s.

What are the key principles of OEE?

OEE is based on three key factors: Availability, Performance, and Quality. These factors assess equipment availability, operating speed, and product quality.

How do you calculate OEE?

To calculate OEE, determine total available production time, actual production time, ideal cycle time, and then compute availability, performance, and quality percentages. Multiply these three percentages to get the OEE score.

What are the benefits of using OEE tracking?

OEE tracking leads to improved productivity, better process optimization, reduced downtime, lower maintenance costs, enhanced product quality, and increased customer satisfaction.

What are the limitations of OEE tracking?

OEE may not consider external factors, may not provide insights into root causes of inefficiencies, and requires accurate data collection, which can be time-consuming.

What are some tips for using OEE effectively?

Tips include regularly monitoring and analyzing OEE data, implementing preventive maintenance schedules, and involving cross-functional teams to address OEE-related issues comprehensively.

How can OEE tracking be used as a preventive tool?

OEE tracking serves as a preventive tool by enabling organizations to proactively identify and address issues before they escalate, minimizing unplanned downtime and optimizing equipment and processes.