What

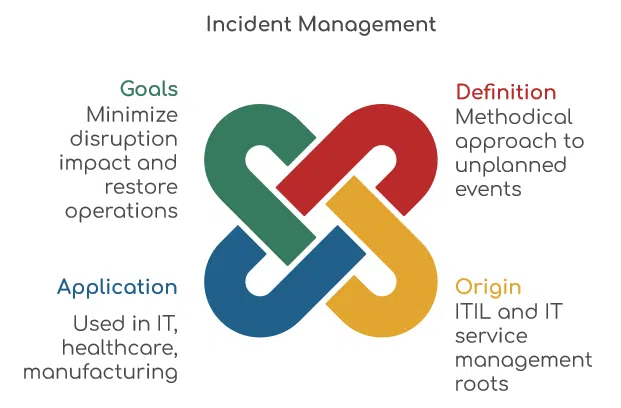

Incident Management is a methodical way of finding, reacting to, and solving unplanned events or problems in a company. In quality management, it is important for keeping and enhancing product or service quality by quickly dealing with any changes, interruptions, or failures in processes.

Incident Management originated in IT service management, especially within the Information Technology Infrastructure Library (ITIL). Its concepts have been adjusted and broadened to fit different sectors beyond just IT over the years.

When

Incident Management is used in various industries like IT, healthcare, and manufacturing. It aids organizations in keeping operations steady, lowering downtime, and improving customer satisfaction by handling and learning from incidents in an organized way.

Why

The main goal of Incident Management in quality is to lower the effects of interruptions on product or service quality. It seeks to return to normal operations quickly and in an organized manner, while also finding root causes to stop future problems.

Principles

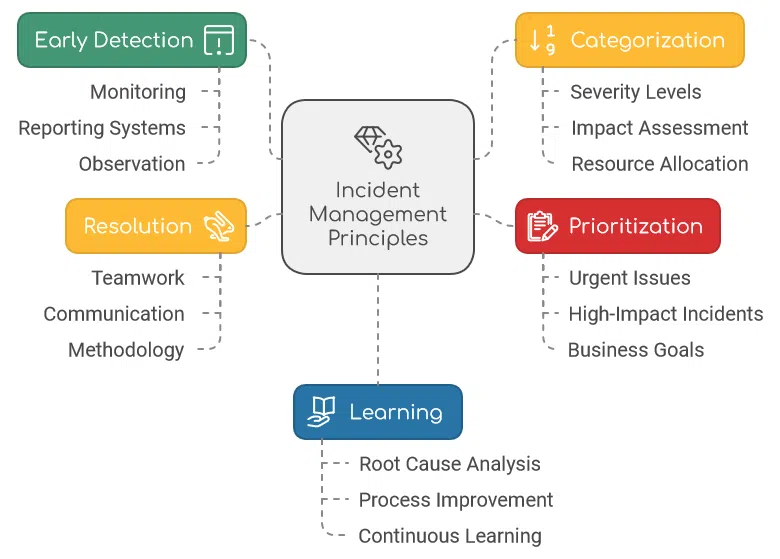

Incident Management is guided by the laws of:

Early detection

Early detection is key in Incident Management, stressing the importance of spotting incidents early on. This allows organizations to react quickly, stopping issues from growing and reducing potential harm to operations and quality.

This principle highlights the need for careful monitoring, active reporting systems, and ongoing observation to quickly catch any deviations from normal operations.

Categorization

Categorization means sorting incidents by how serious they are and how much they affect the organization. This method provides a clear way to respond to incidents, helping to use resources wisely.

By categorizing incidents, organizations can focus on the most important problems first. This sorting also helps with communication within the organization, creating a shared understanding of the urgency and significance of each incident.

Prioritization

After incidents are categorized, the Prioritization rule is used, helping organizations to focus on urgent high-impact incidents.

This makes sure that available resources are used to tackle the most important issues first, reducing possible negative effects on operations and quality. Good prioritization depends on a clear understanding of the business goals and the potential effects of each incident, which enables a focused response.

Resolution

The Resolution principle highlights the importance of quickly fixing and addressing incidents. This means taking actions that not only bring operations back to normal but also stop the same issues from happening again.

Resolution needs teamwork among key people, good communication, and a clear method for applying fixes. Effective resolution helps the organization be stronger and keeps its quality standards up.

Learning

Learning is an important principle that looks at events to find out why they happened. By knowing the main reasons for incidents, organizations can take steps to stop them from happening again.

Learning is about always getting better, where each event is a chance to improve. This idea helps organizations change and upgrade their processes, building a culture of constant improvement and strength when things change.

How To

1. Log the incident

Incident logging starts the Incident Management process. It means writing down details about the incident. This includes explaining what happened, its type, and how it affects operations or quality. Logging incidents correctly and on time is important because it supports the next steps in Incident Management.

Good documentation helps everyone communicate well, helps sort and rank incidents, and gives a history for future review and improvement.

2. Categorize

Categorization is the methodical sorting of incidents into known categories. This process includes arranging incidents by their characteristics, effects, and other important factors. Creating clear categories aids in making the incident management process easier, ensuring a more organized response.

Categorization is crucial for prioritization, as it enables organizations to swiftly evaluate the kind and seriousness of each incident, leading to a clearer and more efficient resolution.

3. Prioritize

Once an incident has been documented and categorized, the next step is prioritization.

This prioritization helps allocate resources effectively and ensures that critical incidents are addressed first. It acts as a decision-making guide to determine which issues need immediate attention and which can wait.

It’s important that priority is based on impact and urgency — not gut feeling. A structured evaluation process ensures that everyone shares a common understanding of what needs to be handled first. This keeps the team focused, enables quick responses to risks, and helps prevent greater damage.

4. Investigate

Investigation is a step for organizations to look into the incident and find out the main reasons. This needs a careful look at the factors that contributed to the incident, trying to know the basic problems that caused the issue. Good investigation needs teamwork among relevant parties, access to important data, and the use of problem-solving methods.

Finding root causes is important for creating lasting corrective actions that fix the current incident and stop it from happening again later.

5. Solve

Solving is the step where we deal with and fix the incident. This phase includes taking corrective actions to get back to regular operations and stop similar incidents from happening.

Successful resolution needs teamwork from the incident response team, clear communication, and following set procedures. The aim is to not just address the issue at hand but also to improve processes for lasting stability and better quality.

6. Document and Learn

Documentation is a important part of the Incident Management process. It means keeping a full record of the incident and how it was solved. This includes logging the incident, categorizing it, prioritizing, investigating, and the steps taken to resolve it.

A good record is helpful for analysis, audits, and improving processes. It offers historical views which help in finding patterns, trends, and where the organization can enhance its incident response.

Benefits

Enhanced Quality

A major benefit of using Incident Management is better quality of products or services. By quickly fixing incidents in an organized way, companies can find and correct problems with quality before they get worse.

This active method helps create a culture of ongoing improvement, making sure that products and services meet or go beyond what customers expect. Quick fixes of incidents not only stop possible flaws but also support a focus on quality within the whole organization, which improves the customer experience overall.

Operational Stability

Incident Management helps keep operations stable by reducing downtime and ensuring business runs smoothly. Quick spotting and fixing of issues stop interruptions to important processes, systems, and services. Less downtime helps productivity and efficiency, letting organizations have a steady workflow.

Stability in operations is important for meeting deadlines, satisfying customer needs, and keeping overall business performance strong. By managing incidents well, organizations can create a strong operational setting that is more ready to deal with unexpected problems.

Customer Satisfaction

One main benefit of Incident Management is how it helps customer satisfaction. By quickly fixing incidents, companies reduce interruptions to services or products, allowing a smooth experience for customers. This active approach shows a focus on customer needs and builds trust in the organization’s dependability. Customers like businesses that manage issues well without hurting the quality or delivery of their services.

Improved customer satisfaction can lead to customers coming back and promotes good word-of-mouth, strengthening the organization’s image in the market.

Limitations

Dependency on Detection and Reporting

Incident Management is a useful method to fix problems, but it relies heavily on accurate and timely reporting of incidents. If reporting has gaps or delays, it may slow down how quickly an organization can respond.

Missing or late information can cause incidents to be misclassified or poorly prioritized, which can affect how well the incident management process works overall. This issue highlights the need for strong reporting systems and a work environment that motivates employees to report incidents quickly as they happen.

Resource Intensive

A main limit of Incident Management is how much it needs resources. Doing incidents well takes time, people, and sometimes money for good investigations, fixing problems, and keeping records. Needing skilled workers and fast responses can put pressure on organizational resources, especially when things are hectic.

It can be tough to balance resource use for incident management with other important tasks, so organizations must think carefully about the costs and benefits to use their resources wisely in keeping an effective incident response system.

Best Practice

Regular Training

An important advice for good Incident Management is to have regular training for staff, making sure they can identify and report incidents well. By having training sessions, organizations help their employees see possible incidents early, promoting a culture of alertness.

Trained staff help with quick and correct reporting of incidents, which improves the Incident Management process. Ongoing training also keeps staff informed about new risks and response methods, strengthening the organization’s ability to face new challenges.

Continuous Improvement

A good practice in Incident Management is to see each incident as a chance to learn and use the data collected for ongoing improvement. By looking at incident data, organizations can spot patterns, main causes, and parts of their processes that need betterment.

This repeated approach helps to improve incident response procedures, put preventive steps in place, and build a culture that values learning and change. Accepting ongoing improvement based on incident data not only boosts the Incident Management system but also helps make the organization's operations and quality management efforts stronger and more efficient.

Pizza-Example

Zero-Defect Pizza: Ensuring High-Quality Operations

Zero-Defect Pizza has also a pizza delivery business that aims to provide flawless pizzas to clients punctually. To ensure quality and keep customers happy, they use Incident Management to deal with any issues that arise in their operations. Here, we will explore how they use each principle and step of Incident Management to reach their goal of “Zero Defect” in their pizza delivery service.

Incident Scenario: Late Delivery and Cold Pizza

A situation happened when a customer got a pizza 20 minutes late, and it was not warm when it arrived. This caused a customer complaint, which Zero Defect Pizza considers as very important because it affects customer happiness directly.

1. Log incident

A staff member inputs the incident into the system, noting delivery time, temperature on arrival, and customer opinions. It’s labeled as a “Quality Incident – Late and Cold Delivery,” which could affect customer happiness.

Purpose:

This log helps keep things clear and allows everyone to understand how the incident impacts business and customer relations.

2. Categorize

Category:

The incident is categorized under “Delivery Issues” and “Temperature Control Issues.”

Purpose:

This categorization enables the team to quickly recognize recurring issues and guides them to a solution protocol for delivery and temperature problems. It also allows managers to allocate resources based on known problem types.

3. Prioritize

Priority Level:

The incident receives high priority due to its negative effect on customer satisfaction and potential harm to brand image.

Purpose:

By making this issue a priority, the company ensures that the team pays attention immediately, reassigning resources to investigate and fix this high-impact issue before it happens again.

4. Investigate

Process:

The team looks into possible root causes, checking factors such as:

- Order preparation time: Was the pizza made and allowed to cool before the driver got there?

- Driver delay: Did the driver get stuck in traffic, or was there a mistake in the delivery address?

- Packaging: Did the packaging fail to keep the pizza warm?

Outcome:

The investigation shows that the delay was due to the order being incorrectly marked as ready too soon, leading to a 15-minute wait for the driver.

5. Resolve

Actions Taken:

Based on findings, the following steps are taken:

Process change:

The company updates its order system to mark pizzas as “ready” only when they’re in a warming oven.

- Staff training: Delivery drivers and kitchen workers are retrained on timing to ensure pizzas leave right after they’re ready.

- Improved packaging: Tested insulated delivery bags start being used to keep heat longer.

Goal: By refining software and staff practices, Zero-Defect Pizza aims to prevent future delays and preserve pizza quality during delivery.

6. Document and Learn

Record Keeping:

The incident, investigation, and corrective measures are documented. This log allows for pattern analysis, checking if delivery issues arise often and need better processes.

Learning Outcome:

Team leaders study data over months and notice incidents happen more on weekends. They add staffing and change scheduling to guarantee timely deliveries during busy times.

Results

Better Quality:

By fixing problems in making, timing, and packing, Zero-Defect Pizza lowers the chance of cold pizzas, making sure customers get a hot and fresh item.

Steady Operations:

Solving timing and messaging issues ahead of time results in more stable operations, cutting down on problems and lessening customer complaints.

Customer Happiness:

Fast and clear reactions to issues produce a good experience for customers, strengthening their belief in Zero-Defect Pizza’s promise of quality.

FAQ

What is incident management?

How is incident management typically used?

Incident management is used to respond to incidents that can impact product or service quality. It involves documenting, analyzing, and resolving issues to prevent their recurrence.

What is the primary objective of incident management?

The primary objective is to ensure that quality standards are met consistently by identifying and addressing deviations promptly.

What is the history of incident management in quality management?

Incident management has its roots in various quality improvement methodologies, such as Total Quality Management (TQM) and Six Sigma. It has evolved as a crucial component of quality control in modern industries.

What are the key principles of incident management?

The key principles on incident management include:

- Early Detection: Identifying incidents as soon as they occur.

- Documentation: Thoroughly recording incident details.

- Analysis: Investigating root causes to prevent recurrence.

- Corrective Actions: Implementing solutions to mitigate the incident’s impact.

How can one effectively implement incident management in quality control?

To implement incident management, follow these steps:

- Identification: Recognize and document incidents.

- Assessment: Evaluate the impact and severity.

- Investigation: Analyze the root causes.

- Resolution: Implement corrective and preventive actions.

- Monitoring: Continuously track and review incidents.

What are the benefits of using incident management in quality control?

The benefits include:

- Improved product quality.

- Enhanced customer satisfaction.

- Reduced waste and defects.

- Increased operational efficiency.

- Continuous improvement culture.

What are the limitations of incident management in quality control?

Limitations may include:

- Incomplete incident reporting.

- Inadequate data analysis.

- Resistance to change.

- Resource-intensive.

- Focus on symptoms, not underlying issues.

What are best practices for effective incident management in quality control?

What is an example of incident management in quality control?

A manufacturing company that produces electronic devices. They notice an increase in customer complaints about defective screens. Incident management would involve:

- Identification: Gathering reports of defects from customers and the production line.

- Assessment: Evaluating the impact on customer satisfaction and production costs.

- Investigation: Analyzing the manufacturing process to identify the root cause, which could be a faulty supplier component.

- Resolution: Implementing corrective actions, such as changing the supplier and improving quality control checks.

- Monitoring: Continuously tracking product quality and customer feedback to ensure the issue is resolved and doesn’t recur.