What

The Supply Chain Alert (SCA) is a tool for quality management that informs necessary people about problems affecting the quality, availability, or integrity of an item, like a part or machine, at different locations. These alerts are meant for internal teams, suppliers, or customers to ensure clear communication regarding events that could influence the supply chain.

Traditional quality management systems mainly focused on fixing problems after they happened in separate departments. Now, modern supply chains need quick and clear alert systems that involve multiple departments.

The Supply Chain Alert solution was created to meet these requirements in industries that have complicated supply chains. It uses ideas like Failure Mode and Effects Analysis (FMEA) and works together with digital supply chain management (SCM) systems to improve earlier detection and visibility of quality problems across the entire supply chain:

When

Supply chain alerts warn companies about problems before they get worse. They are used in several key scenarios:

- When quality issues are detected in components or raw materials

- When material shortages occur that could impact production schedules

- During unexpected disruptions like natural disasters, political instability, or transportation issues

- If a supplier faces operational difficulties or potential bankruptcy

- When there are significant delays in shipments or logistics breakdowns

- During cybersecurity incidents affecting supply chain systems

- When compliance or regulatory issues arise with suppliers or materials

- If sudden demand spikes create fulfillment challenges

These alerts help organizations respond quickly to minimize operational impact, coordinate alternative solutions, and maintain communication with affected stakeholders throughout the resolution process.

Why

Supply chain alerts aim to solve problems quickly and protect business flow. Their first goal is to manage issues across the entire supply network. They also speed up communication between teams when problems happen.

Another key goal is cutting response time. When alerts work well, companies fix issues in hours instead of days. They also help prevent bad products from reaching customers.

The system works by watching for trouble signs and telling the right people right away. This helps companies stay ahead of problems. Teams can work together to find solutions before small issues grow into big ones.

Good alert systems save money and keep customers happy. They turn supply chain risks into manageable events rather than major crises.

Principles

Speed

Timeliness is essential in the Supply Chain Alert system to lower risks and lessen disruptions. A quick response can mean the difference between fixing a problem in one place or letting it grow into a wider issue that impacts many sites or customers. By sending alerts quickly, companies can stop using or sending out affected products, cutting down on potential problems with safety, regulations, and customer satisfaction. This principle highlights the need for quick communication and stresses immediate actions, making timeliness vital to avoid costly delays or defects from spreading in the supply chain.

Transparency

Transparency is key in the Supply Chain Alert system. It makes sure that all parties know about any quality problems as they happen. By giving clear information to everyone who might be affected, transparency helps stop misunderstandings or mistakes. This openness about supply chain issues allows all parties, from suppliers to customers, to see the problem, expect possible effects, and take the right actions. In tightly linked supply chains, transparency builds trust and encourages teamwork to address quality issues, which strengthens resilience in the supply network.

Exception-Based Alerting

Exception-based reporting is a crucial element of Digital Supply Chain Alerts. It focuses on alerting supply chain stakeholders only when deviations from predefined standards or thresholds occur. Instead of inundating users with constant notifications, this principle filters information, highlighting events that require attention. This approach minimizes alert fatigue, allowing supply chain professionals to concentrate on critical issues that demand immediate action, ultimately improving overall decision-making and resource allocation.

Responsibility Allocation

Responsibility allocation makes sure that each alert clearly states who is in charge of handling the incident, solving the issue, and coordinating the response. In complicated supply chains, where incidents can affect many stakeholders, clear responsibility helps avoid confusion and delays in response. It lets every person or team know their role and focus on their tasks, such as quality control, production changes, or talking with outside partners. This principle supports accountability and effective incident management, helping everyone involved act decisively and in line with their duties.

How To

1. Define the alert criteria

To make the Supply Chain Alert system work well, first, clear criteria have to set up what counts as an alert. This means finding specific triggers, like not meeting quality standards, safety risks, or compliance issues.

The criteria should be broad enough to include important situations but should avoid sending too many unnecessary alerts which might lead to people ignoring them. Each company will create these criteria based on its field, product details, and regulations. By setting these standards, critical issues get alerts, focusing attention on serious matters that need fast action.

2. Determine Stakeholders

Once the alert criteria are set, the next task is to find the stakeholders affected by a quality problem. This group can include internal teams like production, logistics, and quality control, as well as external parties like suppliers and customers.

By identifying everyone who might be affected, the alert system makes sure to notify all necessary people. It’s also important to note each stakeholder’s role and their involvement in addressing the problem. Proper identification of stakeholders helps make sure the right people are informed and ready to act, leading to better teamwork and less damage from the incident in the supply chain.

3. Set up alert mechanisms

With the stakeholders identified, it’s time to set up alert mechanisms for clear communication. This usually involves using a digital tool supported by email notifications, SMS messages, or connections with supply chain management (SCM) software for automated alert distribution.

Each alert should contain key information such as the problem type, affected items, urgency, and initial actions needed. Automated alerts save time by cutting out delays in communication and ensuring that information is consistently shared. Making these mechanisms user-friendly helps everyone quickly understand the alerts and act accordingly.

4. Assign duties

Assigning duties for incident management is key for a well-organized response. For each incident type, identify who handles the alert, looks into the root cause, and coordinates with others for corrective actions.

This may involve assigning roles to specific quality managers, engineers, or logistics staff based on their skills and influence. Clear duty assignment creates an organized response, limiting confusion and avoiding duplicated work. When each team member knows their tasks, deadlines, and goals, it encourages accountability and helps solve issues faster.

5. Monitor und track

After an alert goes out, constant monitoring and tracking of response actions are critical. This means keeping a record of the alert’s status, following up on tasks, and checking progress until the issue is fully fixed. Many companies use SCM software or quality management systems to log actions and monitor progress automatically, giving real-time updates on the situation.

Monitoring not only ensures the issue gets addressed but also provides a record for future reference. Regular tracking helps keep the response effective and allows for adjustments to ensure timely resolutions.

6. Review and learn

Once an incident is resolved, it’s important to review the situation for ongoing improvement. This involves looking at what happened, why, and how the response was conducted. Methods like root cause analysis or failure mode and effects analysis (FMEA) help find underlying causes and potential improvements for the future.

Preventive steps. Looking at incidents after they happen can give useful information about where processes are weak, or what needs better alert rules or training. By understanding each incident, the organization can make changes to stop similar problems from happening later, helping to build a stronger and more flexible supply chain gradually.

Benefits

Enhanced Responsiveness

One notable advantage of the Supply Chain Alert system is that it helps respond better to quality problems. When a problem is found, the alert system sends out quick notifications to all needed parties, allowing them to act fast to manage the issue. This better responsiveness cuts down on the time between discovering a problem and starting corrective actions, which helps stop small issues from growing into big quality failures. With this improved reaction speed, organizations can keep their production schedules on track, lessen downtime, and ensure product quality, leading to higher customer satisfaction and a stronger brand.

Improved Communication

The SCA tool enhances communication within the supply chain, making sure all involved parties—like teams, suppliers, and customers—are informed together. By making how information is shared more uniform, the system cuts down on misunderstandings and avoids the need for repeated updates across teams. Stakeholders get clear and timely information about what the issue is and how it affects them, detailing what actions are needed. This clarity helps avoid confusion, encourages teamwork, and builds trust among all participants in the supply chain, especially in complex operations with many locations where cooperation is crucial.

Risk Reduction

One main benefit of the Supply Chain Alert system is its skill in reducing risk by stopping damaged or non-compliant products from reaching consumers. By quickly notifying the right people about quality issues, the system allows for prompt action, letting potentially affected products be located, separated, or fixed before moving further along the supply chain. This proactive stance lowers the chance of expensive recalls, warranty claims, or damage to reputation that could happen if low-quality products get sold. Risk reduction through quick alerts boosts the organization’s reputation for dependability and quality, giving it a clear edge over competitors.

Data-Driven Decisions

With complete records of each alert and how it was handled, the SCA tool supports decision-making based on data. Each alert provides important information about incident types, how often they happen, root causes, and time taken to resolve them. Analyzing this data over time can highlight trends, ongoing issues, or weaknesses that need addressing. Decision-makers can then focus on improvements that will have the most impact on quality and operational efficiency. Data-driven insights enable targeted enhancements and help plan for resource distribution, training, and risk management, leading to a stronger supply chain.

Documentation and Compliance

The Supply Chain Alert system aids in documentation and compliance by keeping clear records of every alert, the actions taken, and the resolutions. This careful documentation is vital for meeting regulatory and industry standards, as it offers a clear trail that auditors, customers, or quality inspectors can review. Furthermore, these records help internal quality checks and can be used for ongoing improvement efforts. Having organized documentation minimizes the risk of compliance issues and establishes accountability, demonstrating that the organization actively manages quality and supply chain risks.

Limitations

Complex Configuration

Setting up an SCA system is hard because it needs specific workflows and rules for different types of incidents and stakeholders. To make this easier, organizations should map out alert types and create clear criteria and templates for each category. Automated workflows can help manage alerts based on set rules. Consulting with supply chain or quality management experts during setup and regularly checking configurations can help keep the system aligned with business needs and changes.

Resource Intensive

Handling alerts can take a lot of resources, especially for organizations with many incidents, as each one needs time, staff, and budget. To lessen this burden, organizations can create an alert triage system that focuses on high-impact incidents first and schedules minor alerts for later review. Forming cross-functional teams, where members from different departments share alert duties, can lighten the load and avoid burnout. Using data analysis to find and fix repeated issues can also lower the number of alerts over time, saving resources.

Potential for Incomplete Coverage

In complex supply chains, some alerts might not reach all stakeholders, like secondary suppliers or remote sites, leaving them out of the loop. To address this, organizations should keep their contact lists updated and make sure all supply chain members are in the alert system. Having backup communication methods, like SMS or phone calls for urgent situations, can help inform those without system access. Regular checks on stakeholder inclusion can improve overall coverage, ensuring that alerts reach everyone who needs them in the supply chain.

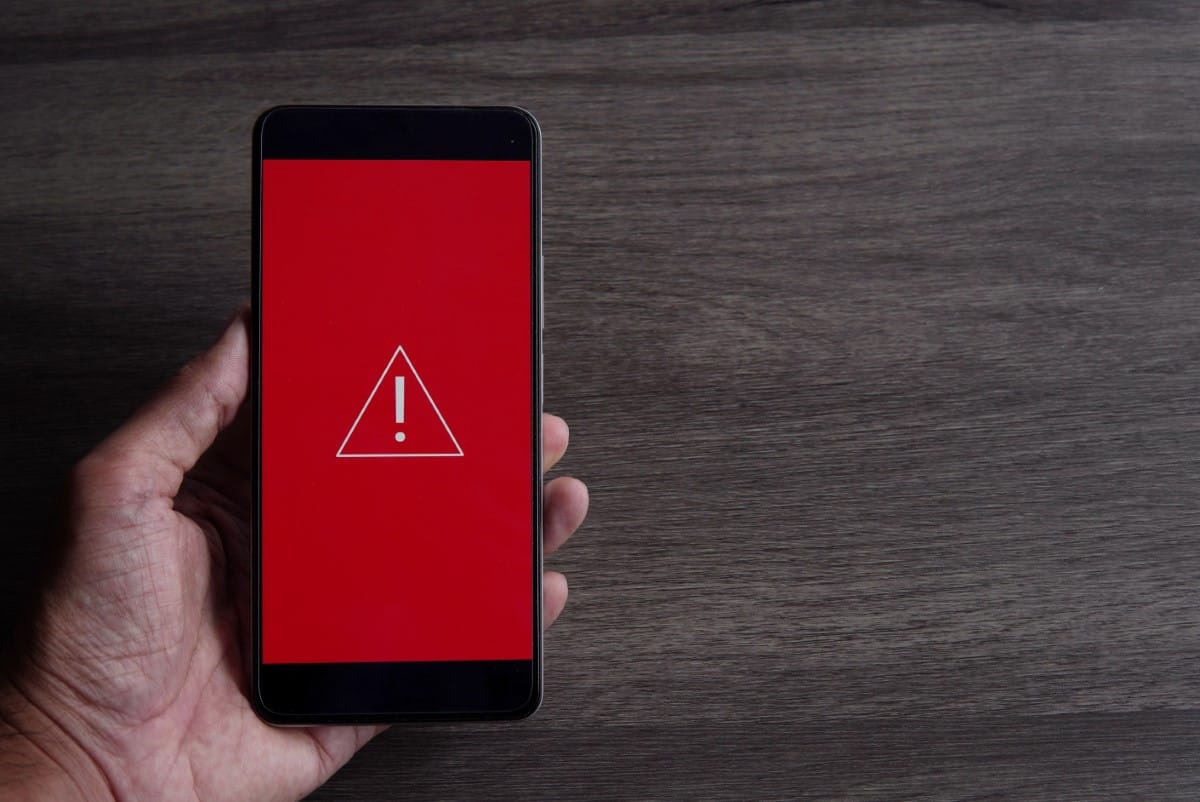

Data Privacy

Another limitation to think about is the worry regarding data security and privacy. As companies gather and send real-time data from different supply chain sources, it is important to protect the confidentiality and integrity of this data. Data breaches or unauthorized access to sensitive supply chain information can lead to significant problems, such as disrupting business operations and revealing confidential information. Tackling data privacy issues through strong security measures and adherence to relevant regulations is essential when adopting Digital Supply Chain Alerts.

Best Practice

Use Priority Levels

Setting priority levels in the Supply Chain Alert system is a useful method to make sure important issues get quick attention while less urgent ones do not overload the recipients. By sorting alerts into high, medium, and low priority, organizations help stakeholders see and tackle issues that might negatively affect quality, safety, or production the most. This prioritizing helps avoid alert fatigue by filtering out minor problems that do not need a quick response, allowing teams to focus on issues that truly need instant action. Clear rules for each priority level also assist employees in assessing urgency consistently and responding properly.

Regularly Update Contact Lists

The effectiveness of the SCA system relies on accurate and up-to-date contact lists for all stakeholders, including internal team members, suppliers, and customers. Regularly updating these lists helps ensure that alerts reach the right individuals without delays, avoiding potential communication breakdowns. Contact information can change frequently due to personnel changes, organizational restructuring, or supplier network expansion, so it’s essential to maintain this information proactively. Implementing a periodic review schedule—such as quarterly updates or following organizational changes—can help prevent miscommunications and ensure alerts are received by all relevant stakeholders in the supply chain.

Integrate with Root Cause Analysis

Linking root cause analysis (RCA) with the alert response process improves the SCA system's ability for continuous enhancement. After fixing a problem, conducting RCA reveals the main reasons behind the issue, giving helpful information to stop it from happening again. Organizations can use methods like Fishbone Diagrams or the "5 Whys" technique to carefully explore root causes and take preventive actions. This strategy not only addresses the current issue but also strengthens quality control and lowers the chances of similar problems happening in the future. RCA integration transforms each alert into a chance for long-lasting improvement and a stronger supply chain.

Automate Wherever Possible

Automation can greatly improve the effectiveness and reliability of the Supply Chain Alert system. Setting up automated processes for common notifications, reminders, and escalations allows organizations to lessen manual work, lower the risk of human mistakes, and make sure alerts reach stakeholders promptly. Automation also standardizes alert formats and responses, helping recipients quickly grasp the issue and react properly. Connecting automation with SCM software or quality management systems enables alerts to be sent based on set criteria, like threshold violations or compliance issues, ensuring fast and dependable communication throughout the supply chain.

Conduct Regular Training and Simulations

Ongoing training and incident response simulations are crucial for making sure all team members know how to use the Supply Chain Alert system properly. Training sessions can help staff learn about alert procedures, priority levels, and response roles, making certain they understand what to do when an alert comes up. Simulating potential incidents allows teams to practice and enhance their reactions in a controlled setting, spotting any weaknesses or areas needing improvement. These activities boost team readiness, build confidence, and support a smooth, effective response during real emergencies, reducing delays and improving overall response quality.

Use historical data to refine alert thresholds and criteria

Historical data is useful for improving alert levels and standards. Looking at old alerts and results helps organizations understand how their alert system works. This examination finds patterns and trends, making it possible to tweak alert settings to match real supply chain situations more accurately. For instance, by checking old temperature alert data, a firm can adjust temperature limits to cut down on false alerts and enhance response plans. Using historical data this way supports ongoing progress in the efficiency of Digital Supply Chain Alerts.

Pizza-Example

Supply Chain Alert: Zero-Defect-Pizza – Issue with Dough Quality

Issue with Dough Quality at Supplier Site

Alert ID: ZDP-2023-001

Priority Level: High

Date and Time of Issue: October 27, 2023, 10:30 AM

1. Incident Description

A quality control inspection at one of Zero-Defect-Pizza’s dough suppliers, Dough Masters Co., identified a batch of dough with incorrect pH levels, which could impact the taste, texture, and safety of the final pizza product. The deviation in pH levels was detected during routine testing, indicating potential issues with raw ingredient quality or production processes at Dough Masters Co.

2. Affected products

- Pizza dough batches with Lot Numbers: DMC202310-101 through DMC202310-150

- Production dates: October 25 – October 26, 2023

3. Potential impact

The affected dough batches may compromise the quality standards of Zero-Defect-Pizza products. Using this dough could lead to:

- Off-flavor or texture, affecting customer satisfaction.

- Possible spoilage risks, reducing shelf life and increasing waste.

4. Issue with Dough Quality at Supplier Site

Immediate Actions Required:

1. Production Facilities:

Halt use of affected dough batches immediately. Inspect storage areas to confirm none of the impacted batches are in active use. Separate and label affected stock clearly as “Hold for Review.”

2. Logistics and Warehouses:

Ensure that none of the impacted batches are in transit to retail outlets or distribution centers. Arrange return logistics for affected batches to Dough Masters Co. if already dispatched.

3. Suppliers (Dough Masters Co.):

Investigate the root cause of the pH discrepancy. Report findings within 24 hours, including details on raw materials used, process control data, and any corrective actions planned.

4. Quality Control Team

Conduct further testing on held batches to verify the extent of quality deviation. Complete tests within the next 12 hours and communicate findings to all stakeholders.

5. Sales and Customer Service:

Prepare to inform key clients or partners if a recall is required. Monitor and document any customer complaints related to recent dough quality.

5. Contact persons

- Quality Control Manager: John Smith – QC@zerodefectpizza.com – (123) 456-7890

- Supplier Account Manager: Emily Green – supplychain@zerodefectpizza.com – (123) 456-7891

- Logistics Coordinator: Mike Johnson – logistics@zerodefectpizza.com – (123) 456-7892

7. Next steps

- Report findings from the root cause analysis by October 28.

- Implement corrective actions as needed and verify new production batches for compliance before resuming deliveries.

- Document all actions taken in response to this alert for future reference and continuous improvement.

8. Follow-Up Review

A follow-up meeting will be held on October 30, to review the incident, discuss preventive measures, and update the response protocol if necessary.

Supply Chain Incident: Dough Quality Issue

FAQ

What is Supply Chain Alert (SCA)?

The Supply Chain Alert (SCA) is a tool for quality management that informs necessary people about problems affecting the quality, availability, or integrity of an item, like a part or machine, at different locations. These alerts are meant for internal teams, suppliers, or customers to ensure clear communication regarding events that could influence the supply chain.

Conventional quality control methods mostly concentrated on resolving issues in different areas following their occurrence. Modern supply chains now depend on fast and unambiguous alert systems involving many departments.

Designed to satisfy these needs in sectors with complex supply chains, the Supply Chain Alert tool It combines digital supply chain management (SCM) technologies with concepts like Failure Mode and Effects Analysis (FMEA) to increase earlier identification and visibility of quality issues all along the supply chain.

What are the most common supply chain alert methods?

Exception-Based Reporting

Real-Time Monitoring

Digital Alert Systems

Integrated SCM Alerts

Predictive Analytics-Based Alerts

When is Supply Chain Alert used?

Supply Chain Alerts are used when a disruption, quality issue, or potential risk is identified within the supply chain. These alerts help ensure that the right stakeholders are informed in a timely manner to take corrective action. They are commonly used in areas such as procurement, manufacturing, logistics, and customer service to prevent issues from escalating and to maintain the flow of goods and services efficiently.

Why is Supply Chain Alert used?

The main goal of Supply Chain Alerts is to quickly detect and address supply chain disruptions or quality issues before they escalate. By proactively managing risks, businesses can improve decision-making, minimize errors, enhance collaboration with partners, and ensure the delivery of high-quality products and services to customers.

What are the principles of Supply Chain Alert?

Transparency: Ensures all parties know about quality issues in real time.

Speed: Reduces risks and minimizes disruptions with quick alerts.

Responsibility Allocation: Clearly assigns roles for incident resolution.

Exception-Based Alerting: Prevents information overload by notifying only about critical issues.

How is Supply Chain Alert performed?

Define Alert Criteria – Establish key triggers for alerts.

Determine Stakeholders – Identify involved internal and external parties.

Set Up Alert Mechanisms – Implement email, SMS, or SCM-integrated notifications.

Assign Duties – Clearly define responsibility for issue resolution.

Monitor and Track – Follow up on alerts until full resolution.

Review and Learn – Conduct post-incident analysis to improve future responses.

What are the benefits of Supply Chain Alert?

Enhanced Responsiveness – Enables quick action on quality or supply disruptions.

Improved Communication – Ensures all stakeholders receive timely updates.

Risk Reduction – Helps mitigate potential risks before they escalate.

Data-Driven Decisions – Supports informed decision-making through real-time alerts.

Documentation and Compliance – Ensures records of incidents and responses for audits.

What are the limitations of Supply Chain Alert?

Complex Configuration – Requires detailed setup and integration.

Resource Intensive – Needs dedicated teams for effective operation.

Potential for Incomplete Coverage – May not catch all issues immediately.

Data Privacy Concerns – Involves sensitive supplier and logistics data.

What are best practices for Supply Chain Alert?

Use Priority Levels – Helps in focusing on critical issues first.

Regularly Update Contact Lists – Ensures alerts reach the right people.

Integrate with Root Cause Analysis – Links alerts with problem-solving strategies.

Automate Wherever Possible – Reduces manual effort and speeds up responses.

Conduct Regular Training and Simulations – Prepares teams for real incidents.

Use Historical Data to Refine Alerts – Adjusts thresholds based on past trends.